Product Description:

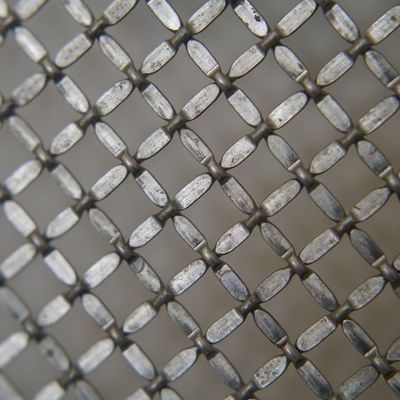

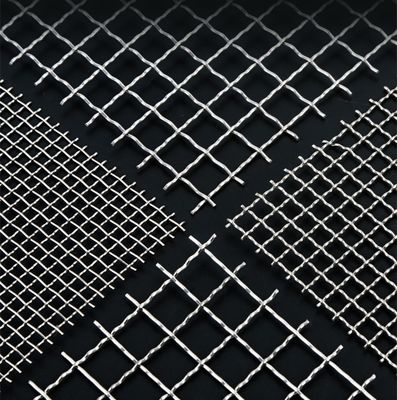

Our stainless steel fine mesh screen is available in a variety of mesh sizes ranging from 1-635mesh, making it suitable for a wide range of filtration and separation applications. Whether you need to filter out fine particles, remove impurities, or separate liquids and solids, our woven screen mesh product is up to the task.

One of the key advantages of our Filter Screen Mesh is its exceptional tensile strength. This means that it can withstand high levels of stress and strain without breaking or deforming, ensuring long-lasting performance even in demanding environments. In addition, our woven wire mesh screens are highly resistant to corrosion, acid, and alkali, making them suitable for use in harsh chemical environments.

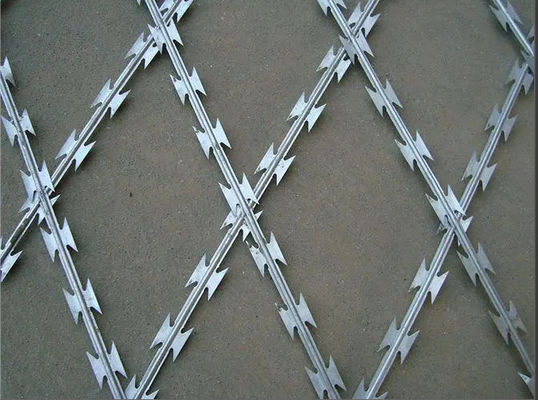

Another advantage of our Filter Screen Mesh is its durability and resistance to damage. Made from high-quality stainless steel, our woven metal mesh screen is fireproof and knife proof, ensuring that it can withstand even the most extreme conditions and maintain its shape and structure over time.

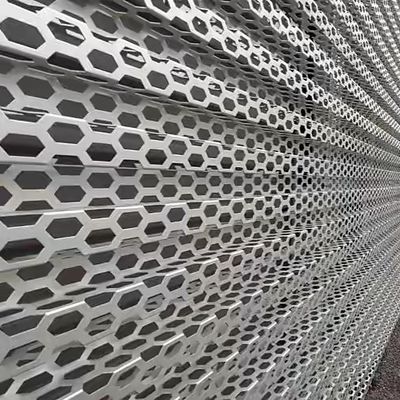

Our stainless steel fine mesh screen is suitable for a wide range of applications, including filtration and separation in the chemical, food and beverage, pharmaceutical, and oil and gas industries. Whether you need to filter out contaminants, remove impurities, or separate liquids and solids, our woven screen mesh product is the ideal choice.

In conclusion, our Filter Screen Mesh is a high-quality woven metal mesh screen that offers exceptional filtration capabilities, outstanding durability and resistance to damage, and exceptional resistance to corrosion and chemical damage. With a range of mesh sizes available and a wide range of applications, our woven wire mesh screens are the perfect choice for your filtration and separation needs.

Features:

-

Product Name: Woven Screen Mesh

-

Surface Treatment: Nature

-

Features: High Tensile Strength, Corrosion Resistance, Acid And Alkali Resistance

-

Color: Black, Gray, White, Yellow Etc.

-

Name: Filter Screen Mesh

-

Material: Stainless Steel

Our Woven Screen Mesh is made of stainless steel, which makes it a durable and long-lasting product. This type of mesh is commonly used as woven wire mesh screens for a variety of applications. Its high tensile strength and corrosion resistance make it ideal for use in harsh environments. Additionally, this stainless steel fine mesh screen is resistant to acid and alkali, which makes it suitable for use in chemical and pharmaceutical industries. The Woven Screen Mesh product is available in black, gray, white, yellow, and other colors to meet your specific needs.

Technical Parameters:

|

Material

|

Stainless Steel

|

|

Features

|

High Tensile Strength, Corrosion Resistance, Acid And Alkali Resistance

|

|

Advantage

|

Durable, Fireproof And Knife Proof

|

|

Mesh

|

1-635mesh

|

|

Color

|

Black, Gray, White, Yellow Etc.

|

|

Wire Diameter

|

0.6mm 0.7mm 0.8mm 0.9mm 1.0mm 1.6mm

|

|

Name

|

Filter Screen Mesh

|

|

Surface Treatment

|

Nature

|

Applications:

The woven screen mesh product has a wide range of applications. It can be used in the food industry to sift and sort grains, flour, and other food products. The woven metal screen can also be used in the mining industry to separate minerals and other valuable materials from waste. Additionally, it can be used in the construction industry to reinforce concrete structures and prevent cracking. The woven wire screen cloth can also be used in the agricultural industry to protect crops from pests and other hazards.

The woven screen mesh comes in different colors, including black, gray, white, yellow, and more. The mesh size ranges from 1-635 mesh, making it suitable for various applications. The product is packaged in standard packing or as per customer demands and has a delivery time of 15-30 days. Payment terms are flexible and can be made through L/C, T/T, and other means.

In summary, the DONGMING woven screen mesh product is a reliable and durable solution for various industries. Its high tensile strength, corrosion resistance, and acid and alkali resistance make it suitable for use in harsh environments. As a helpful assistant, we recommend this product for anyone looking for a reliable and high-quality woven screen mesh solution.

Customization:

We offer standard packaging and can also accommodate special requests from customers. Delivery time is typically between 15-30 days and we accept payment terms such as L/C, T/T, and more.

Packing and Shipping:

Product Packaging:

-

The woven screen mesh will be packed in a sturdy cardboard box.

-

The box will be sealed with strong adhesive tape.

-

A label with the product name, quantity, and dimensions will be affixed to the box.

Shipping:

-

The woven screen mesh will be shipped via a reputable courier service.

-

The package will be tracked and insured for the full value of the product.

-

The estimated delivery time will be provided to the customer upon placing their order.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!