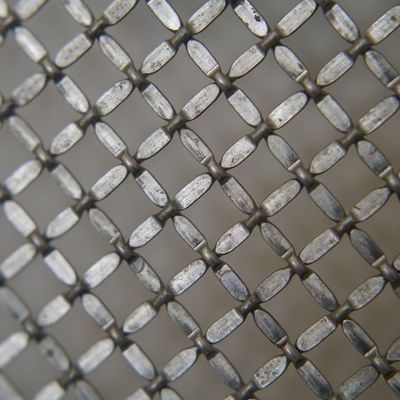

SS woven mesh, also known as stainless steel woven mesh, offers several advantages that make it a popular choice in various applications.

Firstly, its primary advantage lies in its exceptional durability and strength. SS woven mesh is made from high-quality stainless steel wires, which provide excellent resistance to corrosion, heat, and chemicals, ensuring long-term performance even in harsh environments. It can withstand heavy loads and maintain its structural integrity, making it suitable for demanding applications.

Secondly, SS woven mesh offers precise and uniform openings, providing accurate filtration and separation capabilities. The mesh is woven with high precision, resulting in consistent and reliable mesh sizes. This allows for efficient filtration of particles while maintaining optimal flow rates.

Additionally, SS woven mesh offers excellent visibility and airflow. The woven structure of the mesh allows for good visibility while providing sufficient airflow, making it suitable for applications such as window screens, ventilation systems, and air filtration.

Furthermore, SS woven mesh is highly versatile and can be customized to meet specific requirements. It is available in various mesh sizes, wire diameters, and weave patterns, allowing for flexibility in design and application.

Lastly, SS woven mesh is easy to clean and maintain. The smooth surface of stainless steel resists accumulation of dirt and debris, making it easy to clean with simple methods such as brushing or rinsing.

Overall, the advantages of SS woven mesh, including durability, precise openings, visibility, versatility, and ease of maintenance, make it a reliable and preferred choice for a wide range of applications, including filtration, sieving, protection, and separation.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!